It is hard to believe that anything can live and multiply in an aircraft’s fuel tank. But it is a common issue when water is present, and that water is not dealt with. Microorganisms may cause corrosion and affect the aircraft wing structure and wetted fuel system components (such as fuel probes). This can significantly impact flights, affect maintenance and be very expensive to manage.

The greatest concentration of microbes is present when there is water in fuel tanks. As the density of water is greater than fuel, the water will deposit to the bottom of tanks and in the worst-case scenario, lead to corrosion. This situation is worse with water being t in fuel tanks when they aircraft is not being used.

Corporate Jet Investor spoke with Andrew Rushton, head of aviation at Conidia, the specialist fuel testing company, to see how the problem can be managed.

Corporate Jet Investor: How do microbes and water get into aircraft fuel tanks?

Andrew Rushton, head of aviation, Conidia: When fuel is produced at a refinery and transferred into a storage tank, being in contact with ambient air, spores are introduced into the fuel layer, this is the nature of life. Jet fuel combined with the presence of free water will then create an environment for microbes to grow and multiply. Water is the most common contaminant in fuel systems and can lead to many problems, if uncontrolled.

Water may enter the fuel or the fuel system in various ways, such as being introduced during the transportation of fuel; especially via marine vessels, and more readily, as condensation in storage and aircraft fuel tanks. The amount of dissolved water in any given fuel depends on both the composition and temperature of the fuel. Once the fuel is saturated with dissolved water, excess water will be in the form of free water which provides the nutrients and oxygen for spores and bacteria to grow. This is common in tanks that are not drained regularly since in some systems, removal of accumulated water may be sporadic.

A build-up of water in a tank can lead to the development of microbial communities which can then cause corrosion.

CJI: How can anything survive in such a hostile environment?

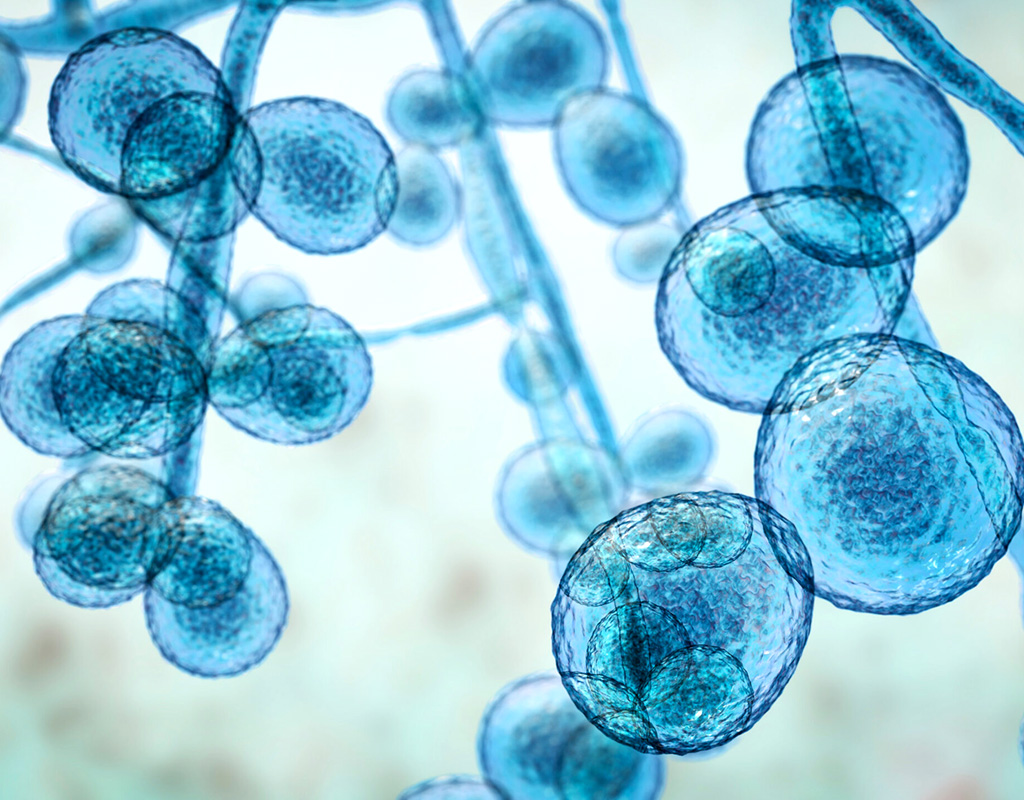

Rushton: Spores and bacteria are present in the air and to some degree in jet fuel, a basic principle of life and the nature of things. There are specific bacteria and yeast that will develop in jet fuel in the presence of free water. These particular aerobic and anaerobic bacteria and yeast will use the hydrocarbon as a nutrient, and oxygen from the water to grow. Known as hydrocarbon degraders, they will proliferate at the fuel/water interface in fuel tanks and if allowed to grow for any extended period, the formation of filamentous fungi will generate a biofilm which can be damageable to fuel system components.

So in essence, despite the austere nature of jet fuel, a small amount of water can be a catalyst for these microbial species to develop and contaminate your fuel system.

CJI: Why is it an issue?

Rushton: Once it takes hold, flight safety becomes a real concern and urgent maintenance action including repairs are needed. Aircraft downtime comes at high costs. Some airlines will try to prevent such a situation by using a biocide treatment, but again this comes at a cost and entrains specific maintenance actions. As microbes multiply, a potentially damaging biomass and corrosive acidic compounds can be generated. Many different types of microorganisms can proliferate in jet fuel. In excess amounts, microbial contamination can cause many problems for aircraft:

The most abundant metabolites produced by microbial communities are low molecular weight organic acids. These can create pitting corrosion in wing tanks, and structural instability. In small jets, it may even result in the need for wings to be removed so that the corrosion can be cut out and the structure restored to a serviceable condition.

As microorganisms grow, they form biomass (accumulation of microbial cells) and biofilms (complex formations of cells and extracellular substances), which can adversely affect several aircraft fuel wetted components such as fuel probes affecting their ability to accurately report the aircraft fuel load. Fuel Quantity Indication System failure can be catastrophic.

An example of microorganism corrosion in an aircraft fuel tank

CJI: How can you work out the risk?

Rushton: The amount of contamination and rate at which microbes grow will depend upon multiple factors, including temperature, volume of water in the fuel, and how long the fuel has been left in the tank. Warmer climates present higher levels of risk.

The issue of microbial contamination and system damage has been amplified during the pandemic. There have been occasions where jets that have been grounded for several months, have been found to have extensive – and costly – corrosion damage when inspected prior to their return to service.

Commercial aircraft are tested periodically for fuel contamination within fuel tanks, but smaller jets may be even more susceptible to microbial contamination as they often spend longer periods on the ground, giving the microbial populations time to form and grow.

Agitating fuel helps prevent water, particulates, and microbes from pooling in any part of the fuel tank, and, if a jet is in more regular use, the fuel supply is more frequently refreshed. By reducing the amount of water in aircraft fuel tanks, water scavenging systems provide a level of security against the accumulation and development of microorganisms which can cause operational issues, but regular testing is recommended to ensure any contamination does not go unnoticed.

CJI: How can you find out if your fuel is contaminated?

Rushton: Testing at the tank provides jet operators with a quick, easy, and relatively low-cost method of helping to ensure that contamination is not allowed to cause damage to fuel tanks and systems.

Testing frequency will depend on aircraft operating conditions and climate, but, in general, it is recommended that even with regular operation and water draining every seven to fourteen days, tests to show levels of microbial growth in fuel should be carried out at least once per year and preferably every six months, especially during spring/summer as weather patterns change. If a jet is not in operation for longer periods, most OEMs recommend that water is checked and drained every seven days and testing for microbial contamination carried out every month.

CJI: Why test at the tank?

Rushton: Although fuel samples can be sent to a laboratory for testing, testing at the tank offers a quicker and more accurate solution. As the microbes within the fuel are living organisms, their population can change over time and with changes to their environment. This means that any samples sent to a laboratory need to be transported quickly and under environmentally controlled conditions.

Single-use immunoassay test kits, based on the same technology as pregnancy or COVID lateral flow test kits, require no special handling or training, give results in a matter of minutes, and avoid the logistical challenges of transporting fuel samples. They provide an excellent preventative maintenance solution with accurate results and indication of contamination levels, which can be immediately shared and logged for trending purposes. Depending on results, testing intervals can be tailored to ensure a robust regime is in place to best protect the aircraft.

Fuel sampling and testing at the tank is straightforward and can be added to day-to-day operations with no special skills or training required. The test takes no more than 15 minutes to complete, and results are available immediately, enabling appropriate action to be taken straight away to help prevent corrosion or damage to aircraft fuel systems. Results can be logged and trended to optimise this simple preventative maintenance regime according to each individual aircraft’s operation and environment. Ultimately, it is a sure and simple way to help avoid the damage that microbial contamination can cause for any type of business jet.

Microbes can cause expensive fuel tank corrosion