It can mean the difference between delivering rotorcraft solutions the Warfighter needs quickly and adding years to the process.

When U.S. Army Combat Capabilities Development Command Aviation and Missile Center engineers developed the Helios software code more than a decade ago, they didn’t just set out to make accurate aeromechanics predictions of rotorcraft performance under a variety of flight conditions – they did it to increase efficiency.

“If you look at the history of Army procurements, a lot of past rotorcraft – almost every one of them in fact – has gone through that phase where they basically have to change the design late in the game,” said Dr. Andrew Wissink, an aerospace engineer with the DEVCOM Aviation & Missile Center. “That drags out acquisition programs, which can really delay the fielding of new vehicles. What we’re trying to do is develop a way to computationally model the detailed high fidelity behavior earlier so that we can predict it ahead of time, before they actually build a vehicle to go and flight test.”

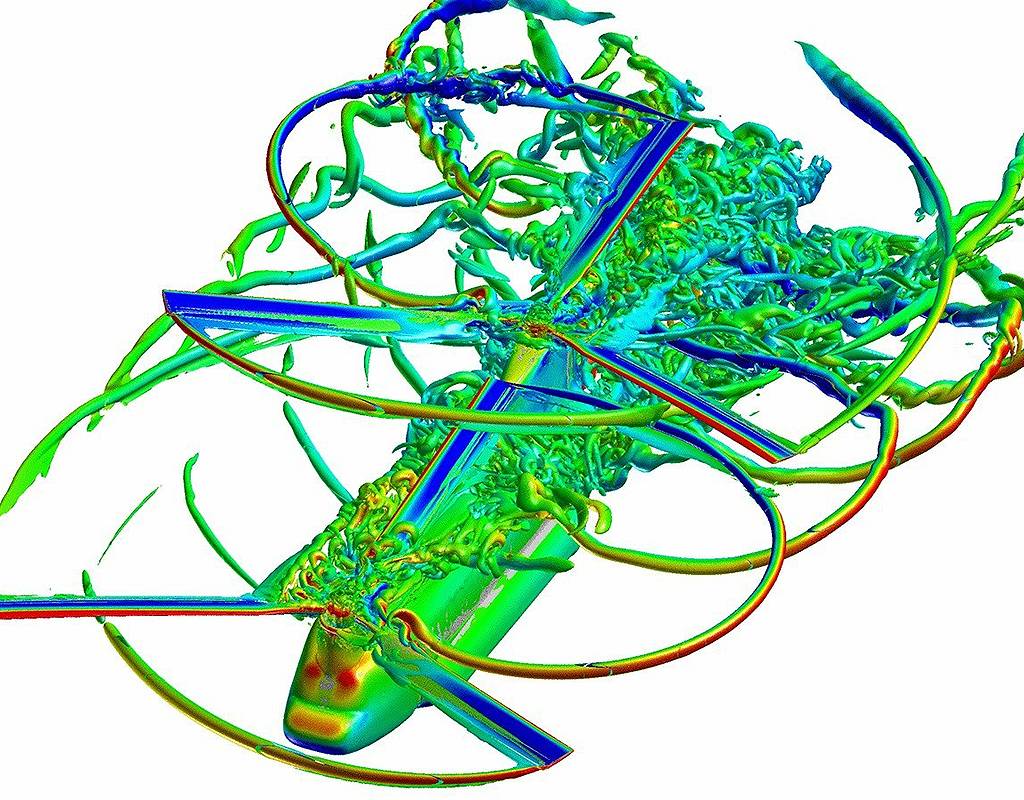

Developed in partnership with the Department of Defense High Performance Computing Modernization Program’s Computational Research and Engineering Acquisition Tools and Environments – Air Vehicles Program, Helios models the coupled aerodynamic and structural dynamics response of the vehicle using computational fluid dynamics codes for aerodynamics, computational structural dynamics to model structural bending, and trim software with multi-body dynamics to set the controls to achieve vehicle trim.

“We can assess what’s happening earlier in the process so that we can reduce the time it takes to get a vehicle in use by the Army, and also make it so that we’re not making late stage design changes, but rather, catching them early so they can be factored into the whole design,” Wissink said.

While it was first released in 2010, major software releases are done annually to ensure Helios stays relevant. Case in point: its use in the development of Future Vertical Lift’s Future Attack Reconnaissance Aircraft and Future Long-Range Assault Aircraft. Rotorcraft designers are also now able to model air launched effects with Helios.

“Helios has enabled us to address rotorcraft aeromechanics for acquisition programs with unprecedented accuracy, efficiency and ease of use,” said Mark Potsdam, an AvMC aerospace engineer performing computational analysis in support of the FVL FARA program. “Simulations have had a significant effect on existing programs, such as CH-47 Block II ACRB rotor and Sikorsky CH-53K Exhaust Gas Reingestion, as well as helped to assess the risk of new Future Vertical Lift acquisition programs, such as FARA, FLRAA and UAS. We can do things in a much more timely and impactful manner than was ever possible before with CFD, while quantifying and furthering fundamental physical understanding of interactional aerodynamics and coupled aeroelastics of unconventional configurations.”

Proof that Helios works is in the impacts seen in programmatic areas, especially over the last few years, Wissink said. For example, in the Marine Corps’ CH-53K program, the test aircraft experienced engine hot gas reinjestion issues. Engineers from the Naval Air Systems Command, Sikorsky and the Army used Helios to identify the root cause, carry out trade studies of exhaust modifications, and propose the most promising and feasible designs that mitigated the issues for flight testing.

“To discover and mitigate that through flight testing alone would have taken a long time. Flight testing remains a critical element in acquisition programs but, with these computational tools, engineers were able to assess it and come up with design changes at a much faster rate than what we’ve been able to do in the past,” Wissink said.

This press release was prepared and distributed by DEVCOM Aviation and Missile Center Public Affairs.