RUAG has concluded a 10-year license agreement with Collins Aerospace for the maintenance and overhaul of rescue hoists for helicopters. As a result, from 2022 its main customer, Switzerland’s Federal Department of Defence, Civil Protection and Sport (DDPS), will benefit from significant improvements in its infrastructure, employee skills and expert knowledge with regard to maintenance and overhaul.

The operational readiness of the helicopters is the key to every successful rescue mission. A professional air rescue that is permanently operationally ready requires the corresponding equipment. If it is established during reconnaissance of the deployment area from the air that a safe landing cannot be made at the site of the accident, rescue hoists can become essential life savers. They are deployed in a multitude of different situations. Rescue hoists are used, for example, in industrial maintenance services for offshore wind farms.

In the future, RUAG will take over the entire maintenance for the 18 European customers assigned to it at the Interlaken site, including overhauls and upgrades of the rescue hoists for various helicopter types. These include the EC135, Bell429, AW109, AW139 and AW169. Thanks to the European time zone, RUAG is closer to its customers and guarantees short delivery times as well as minimal downtime on the ground. In addition to the time component, customers will save on expensive overseas freight costs in the future, as such a rescue winch cannot simply be delivered by courier.

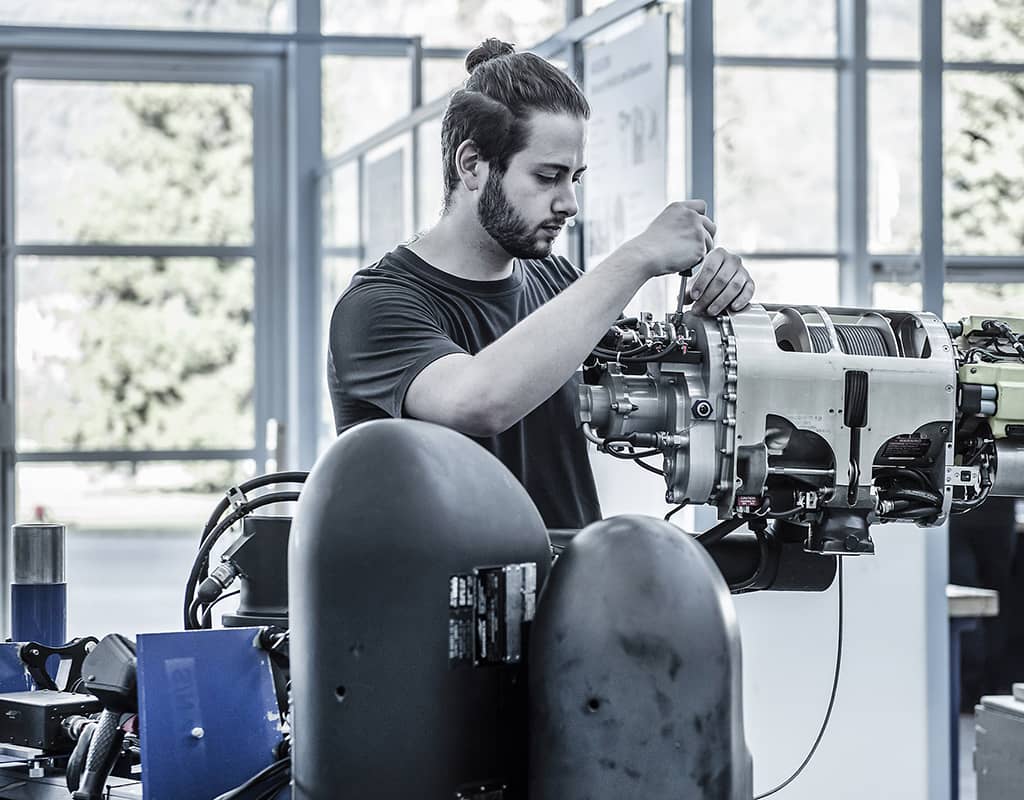

The general overhaul of a rescue winch usually takes just under two months, and every three years the slipping clutch, one of the most important parts, must be replaced. To ensure a short lead time for new customers, RUAG will stock up its warehouse in Interlaken with appropriate spare parts. Due to the new semi-automatic testing system, RUAG is also investing in a modern soundproof room right next to the workstations in Interlaken. This allows short distances and eliminates noise exposure for employees.

Collins Aerospace is part of the Raytheon Technology Group, which has significant offset obligations in Switzerland through its selection as supplier of the Patriot system for the Air2030/BODLUV GR project. Collins Aerospace can use the value generated to meet off-set obligations of Raytheon companies. Agreements of this kind are optimal indirect offset projects, which have nothing to do with procurement for the Swiss Armed Forces and the DDPS, but nevertheless make a contribution to security in Switzerland: These third-party market activities make RUAG’s maintenance services cheaper for the DDPS and sustainably promote capabilities in Switzerland.

RUAG has many years of experience in the maintenance of helicopters. This includes work on engines, rotors and components, as well as comprehensive technical upgrades including spare parts supply, engineering and planning.

Thanks to its close cooperation with Collins Aerospace, RUAG is making an important contribution to saving lives.

This press release was prepared and distributed by RUAG.